SPONSORED CONTENT

Almost every aspect of our current human existence is being documented in a sequence of zeros and ones; every CCTV camera, every tracked GPS journey, every photograph captured and stored, and character typed and sent, marks the infinite accumulation of data that encompasses the virtual record of our presence.

Across the globe, statistics show that data creation is exponentially growing with forecasts anticipating that by 2025, we will have accumulated 163 trillion gigabytes of data worldwide.

To put that into perspective, that’s 11.6 trillion 14TB hard drives.

As our data storage requirements and the cost of data retention continues to grow, it becomes more apparent that innovation in this field is imperative.

Historically speaking, engineers have achieved leaps and bounds in the field of data holding, as hard drives have gotten smaller in size, and higher in capacity.

While current technologies have been making strides in expanding capacity, there has been a physical limitation as to how far it could be pushed, particularly since our IT infrastructure is only as scalable as the largest hard drives available on the market.

Consequently, engineers have still battled with the challenge of finding new ways to squeeze in more data on the same sized hard drives, without destabilising the bits on which the data is written.

Bring on the lasers

The latest leap forward in innovation is being made by the engineers at Seagate who have addressed the need for higher capacity drives by developing a new way to overcome the previous physical limitations of their hard drives through the delivery of new technology that harnesses the power of lasers.

Known as Heat-Assisted Magnetic Recording or HAMR for short, it requires a complete re-engineering of the recording media and the way data is currently being written to the disk.

According to the research, the first HAMR drives will be able to deliver sizes of 20TB+.

Hyperscale environments, such as data centres, will be one of the largest beneficiaries of HAMR technology.

In that space, reliability and capacity is king.

When the HAMR drives hit the market, there will be an immediate benefit to Hyperscale users which will only increase over time as the technology matures and higher capacities are possible.

In order to understand the importance and impact of HAMR, and grasp the way in which it works, we must first explore the existing technology, and the physical engineering behind it.

Under the hood

The first thing to understand is how data is actually stored on a hard drive.

Inside each drive is a rotating metal disk (platter) which contains a lattice of millions of microscopic divots (pits).

In each of those are nanoparticle grains (10-20) which can be magnetically aligned by the writing mechanism of a hard drive.

If it is aligned one way, it is considered a zero and alternatively as a one.

The read head glides over each pit and reports back the alignment which is translated as the data that is stored.

However, the technology has a limitation called superparamagnetism, a term coined by physicists that describes the circumstances where nanoparticle grains are susceptible to thermal fluctuations and can spontaneously flip alignment.

Different types of nanoparticles have different temperature tolerances and as tolerances increase, stronger magnetic fields are required to change the particle alignment.

When the drive head is writing, the magnetic field needs to be perfectly controlled to ensure that the energy output is high enough to align the particle, while also ensuring it doesn’t exceed the particle tolerance in order to avoid data corruption.

The traditional write head consists of two poles that are electrically charged to create a magnetic field under them which was wide enough to fill a pit and affect the nanoparticles inside.

A little history

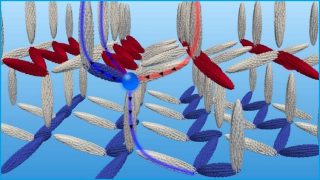

Earlier hard drives used larger pits than we see today which were longitudinal on the platter, meaning that they were laid out flat on the disc along a track.

Pits tended to have more length than width to account for required wide magnetic field usage.

However, due to superparamagnetism, there was a limit to how many pits could be placed on a platter.

Current drive technology instead has pits laid out perpendicular, essentially lined up standing 90 degrees from its original position to compact the amount of space required for each pit and therefore increase capacity.

The write head was also changed to a monopole design and an extra layer of soft material was added under the write layer.

The magnetic field was much thinner under the new design and would pass through the pit, through the under-layer and back to the head.

This allows only the single perpendicular pit to be aligned while also keeping thermals within tolerance.

Bringing the heat

This brings us to Heat Assisted Magnetic Recording (HAMR) drives which Seagate will be releasing later this year. The technology uses perpendicular magnetic recording on a new iron-platinum (FePt) media together with magnetic nanoparticles that are small and thermally stable at room temperature.

The amount of magnetic energy required to align the nanoparticles at room temperature (called the coercivity) is quite high and not feasible.

To lower the coercivity, the pit is heated with a laser so the nanoparticle can be aligned using minimal magnetic energy.

It is then quickly cooled to lock the stored data in place.

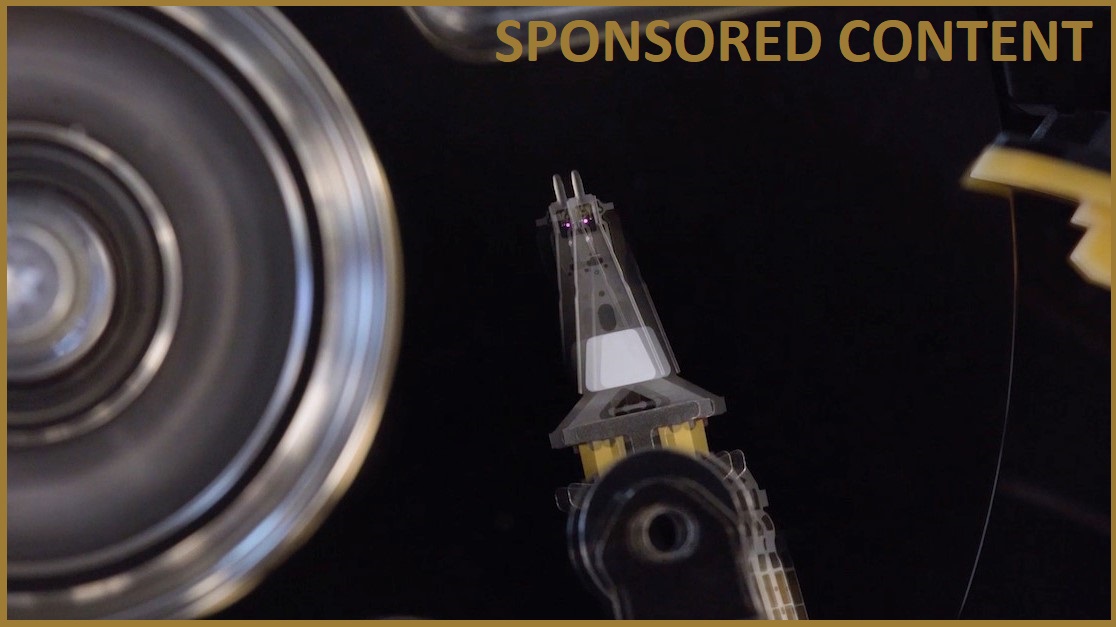

The hard part of making this technology work is that for the laser to do its job, a new type of write head needed to be created.

In addition to adding a laser, Seagate also included an optical waveguide and a near-field transducer (NFT) to facilitate the heating of the media.

NFT explained

The near-field transducer is specifically designed to focus the light from the laser into a smaller point than lasers are capable of hitting on their own.

All light is subject to diffraction which limits the minimal optical spot size.

In a Blu-ray drive, a spot size of 238 nanometer (nm) is possible but for a hard drive, that is far too large.

Even with the best lasers coupled with the use of optical tricks like near-field recording, it would not be possible to get a laser to the required spots of smaller than ~100nm.

This is where the NFT is required.

The Seagate plasmonic NFT is essentially a disk with a peg at the bottom that is the width of the pit being heated.

When light hits the metal of the disk it gets turned into an electric surface current.

This surface current and the associated electromagnetic fields are known as a surface Plasmons which propagate along the surface of the metal.

Using the waveguide, light is directed at the NFT, travels down the edge of the disk and into the peg, heating the precise point on the media.

Seagate has been working on perfecting its NFT technology over the last 15 years and have made more than 25 million plasmonic NFTs during the life of the HAMR development program.

We have the technology. We can rebuild it.

In addition to designing a new write head, the recording media also needed to be completely re-engineered for HAMR as well.

The new platter starts with a special HAMR glass material substrate which allows the recording layer to be laid at high temperature during manufacturing.

Between the substrate and recording layer is a heat sink and interlayer to control the heat flow from the storage layer during writing.

The heat sink’s job is to make sure that flow of heat is ideal as too fast would require too much power and too slow would cause thermal energy to spread and erase adjacent data.

Finally, the overcoat had to be altered so that it would survive being heated to more than 400°C while still managing to maintain a reliable interface between the media and the recording head.

Big storage for big data

Currently, HAMR is on track to deliver 20TB+ drives in volume this year and is forecasted to achieve 40TB or higher by 2023.

However, that isn’t the end of the story.

Seagate is also working on a technology that will combine HAMR with bit patterned media.

It’s called ‘Heated Dot Magnetic Recording’ (HDMR) and the industry consensus is that 100TB drives will be possible with this technology in the future.