A global shortage of computer chips could continue into next year as manufacturers struggle to keep up with high demand.

The sudden onset of remote work, telehealth, and digital lifestyles caused by COVID-19 has driven a high demand for products containing computer chips over the past 12 months and is affecting both consumer and manufacturers.

Semiconductor analyst Harlan Sur said semiconductor companies are currently delivering new chips at a rate between 10 and 30 per cent below demand, according to Market Watch.

“It will take at least three to four quarters for supply to catch up with demand and then another one to two quarters for inventories at customers and distribution channels to be replenished back to normal levels,” Sur said.

For everyday users of high-end computing hardware – like video game enthusiasts – the shortage has made it nearly impossible to get their hands on the latest graphics cards, processors, and gaming consoles.

But the consumer disappointment has not been shared by manufacturers like NVIDIA which just announced it took in US$16.6 billion in 2020, a 62 per cent increase year-on-year, despite the low supply of its flagship RTX 30-series graphics cards.

With interest in cryptocurrency returning over the past year, NVIDIA recently decided to limit the hash rate of its new RTX 3060 cards in order to make it less desirable for cryptocurrency miners, and hopefully put more in the hands of gamers.

NVIDIA said it expects stock levels to remain “lean” until the second half of this year – a sentiment shared by rival chip-maker AMD.

Last month AMD CEO Lisa Su explained the difficulties facing computer chip distribution currently, such as trade tariffs imposed by former US president Donald Trump.

“Not only tariffs, but the COVID environment has increased shipping and freight costs, which are hard to avoid,” she said.

“As we get into a more normal environment, this should improve.”

Manufacturing slows

It’s not just gamers who are missing out on the latest hardware.

US car manufacturers have felt the squeeze and are shutting down factories due to the lack of critical computer chips that go into all manner of modern car production.

General Motors said the supply of semiconductor products is “an issue that is facing the entire industry”.

“GM’s plan is to leverage every available semiconductor to build and ship our most popular and in-demand products,” the US car manufacturer said.

Ford said it expects to lose 10 to 20 per cent of its first-quarter production thanks to the shortage which CNBC estimates could cost the company as much as US$2.5 billion.

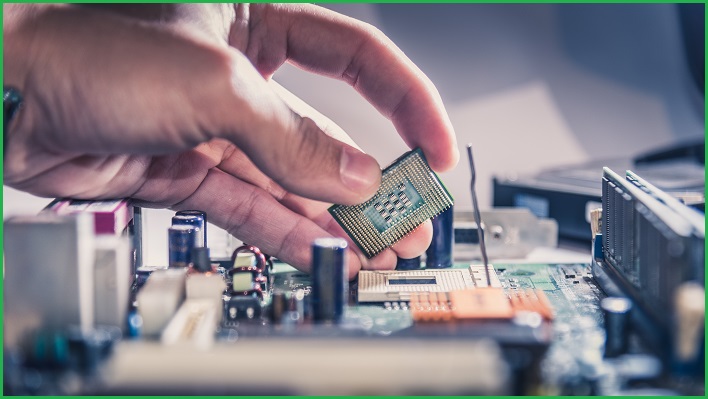

Computer chip production is both complex and time-consuming which means scaling it up to meet high demand is not an easy task.

Falan Yinug, Director of Industry Statistics and Economic Policy at the US Semiconductor Industry Association said you can’t just expect the shortage to be fixed with the “flip of a switch”.

“Restoring market balance takes time,” he said.

“Semiconductor manufacturing is not suited to rapid and large shifts in demand, since it takes time to ramp up semiconductor production.

“Making a semiconductor is one of the most complex manufacturing processes.

“Lead times of up to 26 weeks are the norm in the industry to produce a finished chip.”

Yinug is somewhat optimistic that current shortages will ease in coming months, a sentiment somewhat shared by research manager at the International Data Corporation, Nina Turner.

“Capacity investment decisions made a number of years ago limited the semiconductor industry's ability to respond to sudden change, but supply issues for this market should improve gradually over the next couple of quarters," Turner said.

The chip shortage reached the ears of US President Joe Biden who this week said he would try to secure US$37 billion in funding to boost semiconductor manufacturing in the US.