Charging electric vehicles (EVs) can take many hours and is one of the major hurdles in the wider adoption of the technology.

And it’s something more Australians will face, with sales of EVs booming.

Now a team of researchers has shown promising results with rock salt in batteries that can improve charge time as well as fire safety, and its new company wants to capitalise on the innovation.

EVs, typically powered with lithium-ion batteries, can take many hours, even overnight in some cases, to be fully charged.

This impacts travel time and creates a need for a large number of charging stations, creating impediments to the wider uptake of rechargeable vehicles.

Working on this problem, a team of researchers from the University of California San Diego together with scientists at Oak Ridge National Laboratory experimented with a new type of material hoping it could be developed into better batteries.

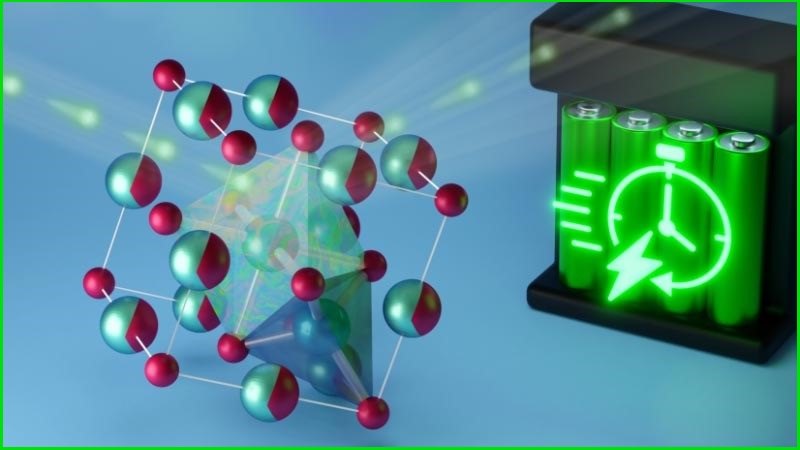

The researchers used what’s called “disordered rock salt” that is similar to table salt except that it has a degree of randomness in the arrangement of its atoms.

Chemically known as lithium vanadium oxide, or Li3V2O5, it was found to have the required qualities that may enable it to be used in EV batteries and other devices such as power tools.

Typically, lithium-ion battery anodes consist of graphite or lithium titanate, but Li3V2O5 can yield a higher cell voltage than a battery using a fast-charging lithium titanate anode or other anode material.

Neutrons track lithium ions in the rock salt anode and the researchers used a technique called “neutron diffraction” to observe the ions when voltage is applied.

Testing showed Li3V2O5 can make available more energy in less time, with the shorter charging and discharging time achieved because it can cycle two lithium ions in and out of vacant sites within its crystal structure.

“Disordered rock salt Li3V2O5 can perform over 1,000 charge–discharge cycles with negligible capacity decay and exhibits exceptional rate capability, delivering over 40 per cent of its capacity in 20 seconds,” the researchers said in their paper.

Reducing battery fire risks

The incidents of mobile phones, laptops, cordless tools and even toys catching fire while charging are well documented.

In Australia, the recent fire in the battery facility in Victoria demonstrates the new safety risk with lithium-ion batteries used in large-scale battery arrays.

It took four days, 30 fire trucks and 150 fire fighters to get it under control.

But it’s not the first, with reports in the UK and US fires in battery storage facilities.

In addition to managing their fire usage while being used, they also pose a risk when no longer used.

“These batteries contain huge amounts of power and at the moment we are still relatively unprepared about how we deal with them when they reach the end of their life,” said Newcastle University (UK) lithium-fire expert, Professor Paul Christensen, who has worked with the UK Fire and Rescue Services on developing protocols for dealing with lithium-ion battery fires.

To mitigate this potential risk, lithium-ion batteries use a slow charge times to ensure charging happens at a stable rate and avoid the build up of particles, known as “dendrites” that can collect and short circuit the battery, potentially causing it to ignite.

To tackle this problem, the researchers also wanted to experiment with reduce the potential for lithium-ion batteries to catch on fire.

The results from Li3V2O5 that show a low-voltage, high-rate capability of the disordered rock salt is from a “redistributive lithium intercalation” mechanism with low energy barriers discovered by the team through computational quantum chemistry-based calculations.

And there are promising signs this discovery could have wider applications.

“This low-potential, high-rate intercalation reaction can be used to identify other metal oxide anodes for fast-charging, long-life lithium-ion batteries,” they said.

Several researchers have now spun off the research to develop commercial applications through Tyfast, working on fast-charging, long-life batteries that limit the potential for fires by restricting internal shorting from lithium-metal plating during fast charging.

They hope to see them used in EV charging stations as well as electric buses and scooters.