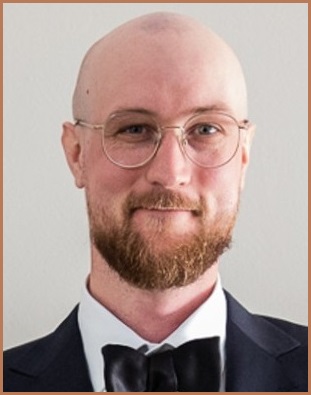

Industry and Science Minister Ed Husic is keen to give Australia’s robotics industry a much-needed shot in the arm and with his department preparing a dedicated strategy to encourage more companies to integrate advanced robotics and automation technologies into their businesses.

Alongside the release of a discussion paper on the forthcoming robotics strategy this week, Husic described automation and robotics as having the potential “to add between $170 billion to $600 billion per year to Australia’s GDP by 2030”.

“It’s also good for jobs, with research showing countries that have invested more in robotics have experienced higher levels of employment growth,” Husic said.

The discussion paper talks up Australia’s existing robotics expertise, mentioning how an Australian-made rover will be part of NASA’s future moon mission and how a CSIRO Data61 team came in second place during a 2021 US Defense Advanced Research Projects Agency (DARPA) robotics challenge.

But the Department of Industry, Science and Resources notes that, despite Australia’s “world-leading” automation in the resources and mining sectors, we generally lag behind in other areas of the economy.

Australia ranked 30th in 2021 for the number of installations of industrial robots, for example, and the department notes we are falling behind other Organisation for Economic Co-operation and Development (OECD) member countries when it comes to robotics adoption.

Husic is, however, optimistic that “Australia has all the ingredients to grow our robotics industry” including “world-class research institutions, a highly skilled workforce and favourable business conditions”.

So far, the primary mechanism for supporting this nascent industry is the $15 billion National Reconstruction Fund which Husic said will “provide investment support” for the local development and uptake of robotics.

This will largely be in the form of loans, credit, bonds, and equity investments in Australian businesses but is split across seven priority areas with critical technologies – a category that covers the likes of artificial intelligence, quantum computing, and robotics – earmarked for just $1 billion from the fund.

Rather than throwing billions of taxpayer dollars toward robotics, the government is instead taking a role that will see it “promote the production and adoption of robotics and automation technologies” through the National Robotics Strategy.

Four key themes for robotics

The Department of Industry, Science and Resources has identified four key themes for its strategy: national capability, responsible development and use, skills and diversity, and increasing adoption.

National capability includes getting businesses across all industries informed about the commercial benefits of Australian robotics and automation while filling gaps in robotics supply chains.

It would also see Australia attract more local and international investment, especially for early-stage robotics companies.

The discussion paper notes that Australia has a relatively high level of venture capital investment in robotics (seventh globally) but underperforms when it comes to commercialisation.

On the responsibility and trust side of things, the government notes a need for industry “to be able to trust that there will be a positive return on their investment”.

Already the department has heard that people feel they can trust technology like robotics more when they feel in control of setting up the system, they understand its benefits, and adoption is normalised.

“Showcasing positive examples of robotics and automation, including the specific benefits this has had on the workforce, as well as broader social and environmental benefits, will help build this knowledge and trust,” the discussion paper said.

The third theme is around having a diverse, skilled workforce that will be developing robotics and automation for Australian organisations which the discussion paper notes can be achieved in different ways.

“We have heard from companies developing and adopting robotics that a range of skills and vocational training levels are required in the workforce,” it said.

“Some roles may require tertiary or post[1]graduate degrees, but in many others, it is trade or vocational skills, or those that can be learnt through on-the-job training.

“In the resources sectors, for example, tailored courses have been developed to upskill and train existing staff in the use of robotics.”

The final theme is adoption, which the department is so far viewing as an education and awareness problem.

Not only are companies unaware of the benefits of robotics and automation technologies, the discussion paper said, but local businesses still prefer “to import well known solutions from abroad” rather than “take on perceived greater risk working with a local manufacturer”.

Costs for small and medium businesses continue to be prohibitive for adoption, likewise the additional training for staff not only in using the tools but for work health and safety.

It notes the role standards, regulation, and legal frameworks have to play in giving businesses more confidence to bring in industrial robots.

Submissions for the National Robotics Strategy discussion paper are open until 7 May, 2023.