Australia’s national science agency CSIRO is calling for industry partners to help take its flexible solar panel technology to market as it opens a new “cutting-edge” facility in Melbourne’s south-east.

The $6.8 million printed photovoltaic plant in the suburb of Clayton is hoped to create “a thriving Australian flexible solar manufacturing industry” amid demand for affordable renewable energy and new industry applications, the agency said.

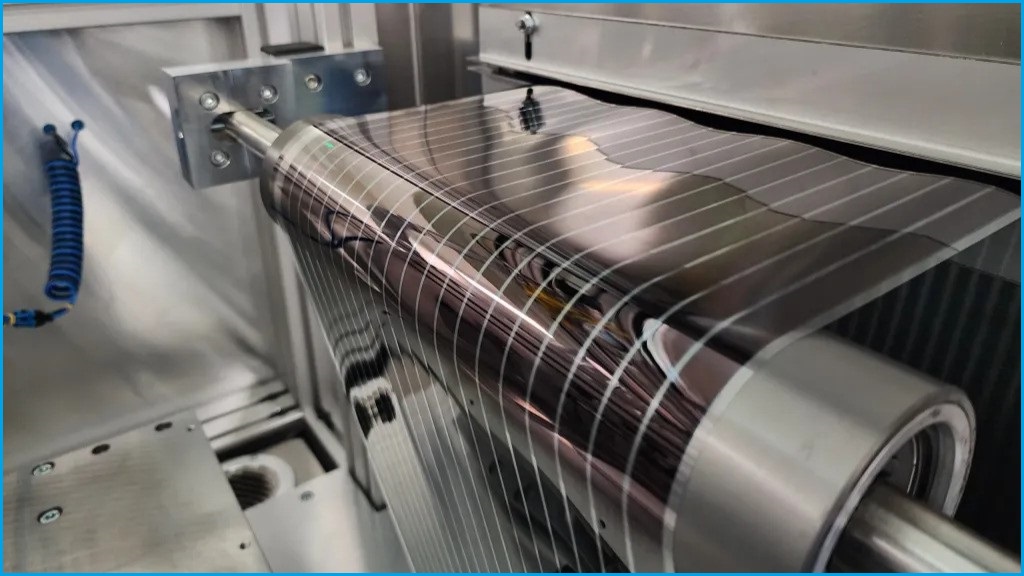

CSIRO’s flexible solar cells are created by printing an advanced material called perovskite onto rolls of thin plastic film, making them lightweight and suitable for many applications across various industries, CSIRO said.

Unlike traditional solar panels which are usually built on crystalline silicon, they are also much more portable.

It means the technology could be deployed in novel ways in settings such as mining operations, construction, disaster relief and emergency management, wearable consumer devices, and even defence and space.

The flexible panels were launched into space in March to test their performance, riding aboard Australia’s largest private satellite, Optimus-1, on SpaceX’s Transporter-10 mission.

The opening of CSIRO’s flexible solar plant comes after its scientists led an international team which set a new efficiency record for printed solar cells earlier this year, reaching 15.5 per cent efficiency on a small scale, and 11 per cent for a 50cm-by-50cm module.

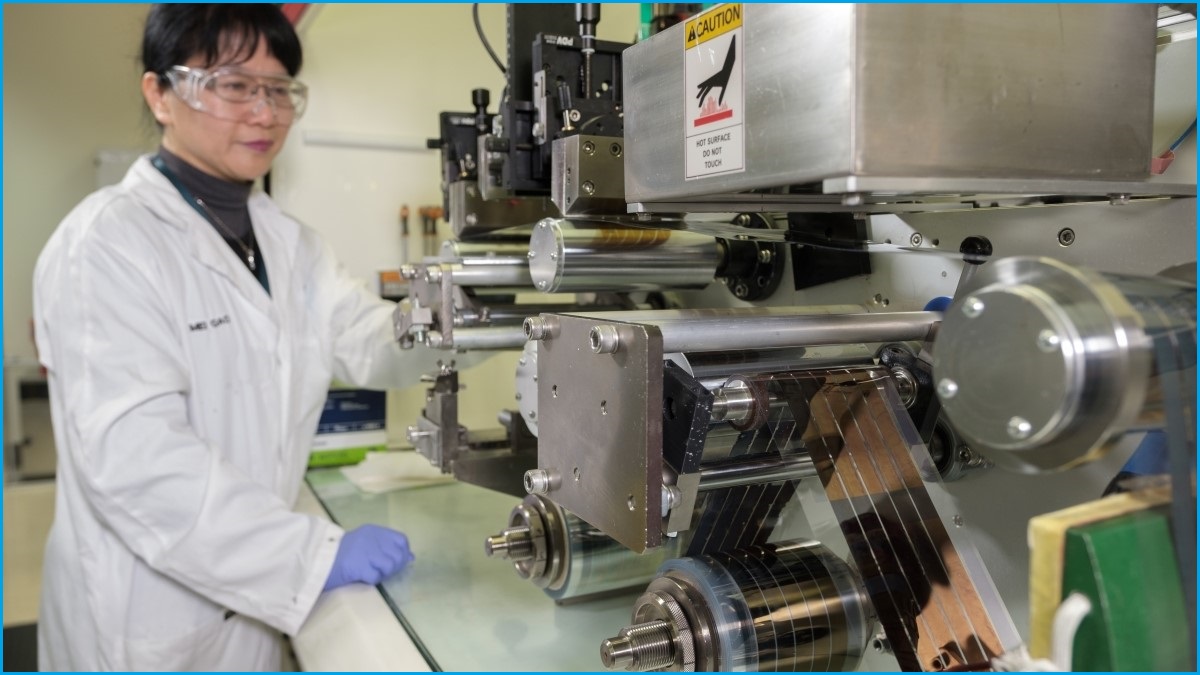

CSIRO says it hopes industry partners will help take its flexible solar technology to market. Photo: CSIRO / Supplied

‘As many as 14,000 test solar cells a day’

Dr Anthony Chesman, who leads CSIRO’s Renewable Energy Systems Group, said printed solar technology unlocked “entirely new applications for affordable, versatile and sustainable energy generation”, but was not designed to replace typical rooftop solar panels.

"Our new system is highly automated,” Chesman said.

“The multiple printing and laminating steps are performed in a single continuous operation, which significantly cuts down on production costs and the upfront investment needed to get started.

“Our team has also developed an automated system that can produce as many as 14,000 test solar cells a day to fine-tune their design and performance.”

CSIRO is looking for partners to become involved in the technology’s development and “ultimately take this technology to market”, Chesman said.

“Our industry partners will gain access to both our cutting-edge equipment and our team of world-class scientists with their deep expertise in solar technology,” he said.

CSIRO's $6.8 million printed photovoltaic plant is in the Melbourne suburb of Clayton. Photo: Nick Pitsas, CSIRO / Supplied

The new Melbourne facility could also examine how printable materials might be applied to other technologies such as batteries and hydrogen power, CSIRO said.

Professor Elanor Huntington, CSIRO’s executive director of national facilities and collections, said the new printed solar facility would help industry partners “apply flexible solar technology in novel ways, anywhere there is sunlight”.

“It’s exciting to see the techniques that enabled another great CSIRO invention to now be available to partners in industry to make a difference in Australia and globally,” she said.

“This not only offers incredible opportunities for Australian manufacturers but also contributes to addressing global energy challenges and advancing the transition to net zero.”

Some CSIRO staff have faced job cuts in recent months.

The organisation’s enterprise services branch — which includes technical, IT, administrative, financial, communication and general management roles — expected to suffer up to 500 job losses as the agency attempted to cut costs by at least $100 million.